Finally made some time to make a valve spring compressor. Yes, these things are expensive. Not if you shop at Harbor Freight though … just buy an 8″ c-clamp for $7.50 (less with 20% off coupon & get a free flashlight, voltmeter, measuring tape, or screwdriver set while you’re at it), get a magnet & stick it on the threaded end, and add a socket with a smaller magnet inside of it. Presto. One functional valve spring compressor. Just make sure to use a flat magnet that won’t crack/shatter when being compressed. Hint: Don’t use the small ones you can get from the inside of a dead hard-drive. They crack/shatter with 3 or 4 turns under pressure. Need to make a trip to Harbor Freight & see if they have anything stronger.

Category Archives: Maintenance

So What’s Next?

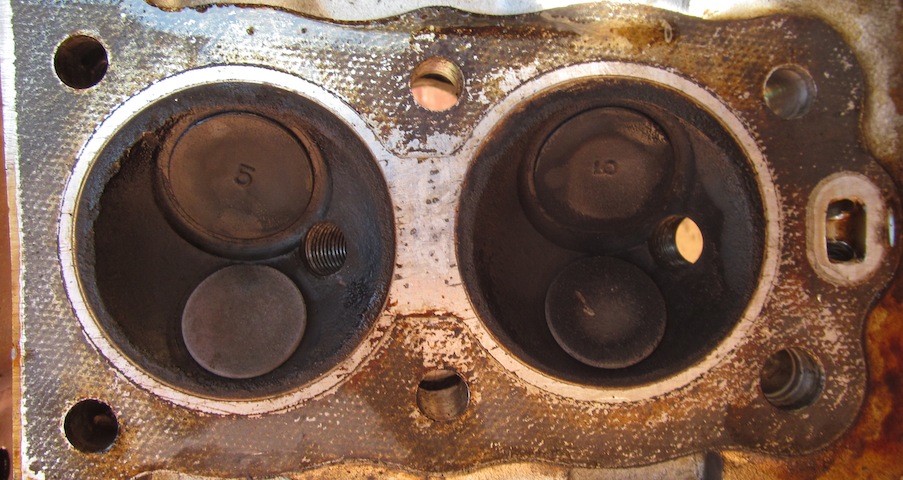

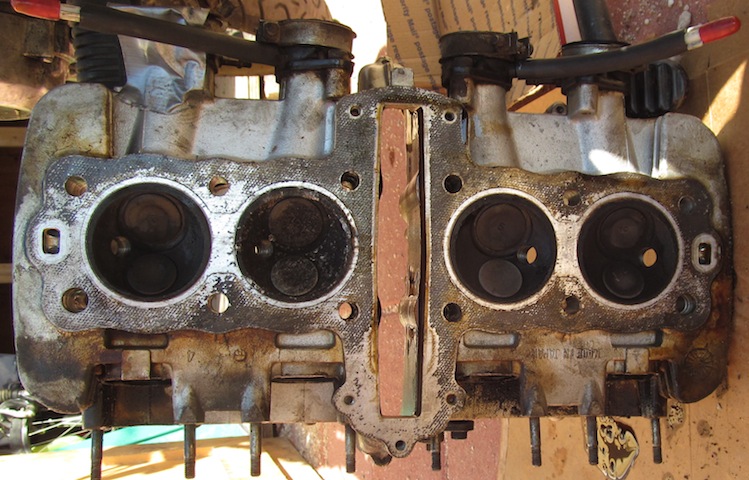

So what’s next? If i keep all of the pieces (pistons, valve/camshaft section) and repair the carbs I still need to replace the gaskets all the way down to the crankcase. The next step is really determining what is still considered good or serviceable. Noting the piece of the carb flap stuck in the valve of #2 there could be more inside of it – so I’ll need to get the proper tool for compressing the valves just to see what condition they are in. Already have a used carb set from ebay so I might be able to scavenge enough parts to get the carbs working properly once they’ve been cleaned (my #2 slide riser is not working proper either), and I’ll need to patch up those flapper holes as well. Hopefully this week I’ll be able to break the carbs down and see what condition the needles, jets, floats & etc are in.