So when working on getting the head and tail lights working last weekend (April 17) squeezing the front brake lever a couple of times worked until there was a frazzling sound & about half power to the brake light. Keying off power and then on again had it working again. Unfortunately while looking at the rear light wiring I heard a small pop from somewhere about the middle of the bike and lost all 12 volt power – so no more blinkers, no more brake light.

Working through the harness showed there was still 12v power off the DC-to-DC converter, and on the line to the ignition switch, but nothing anywhere else. Considering the harness is 38 years old it seemed a good idea to simply rewire from scratch instead of trying to chase down the exact point of failure as when fixing one bad wire there are more waiting to rear their ugly heads.

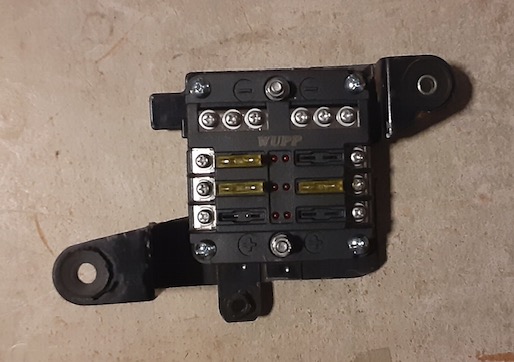

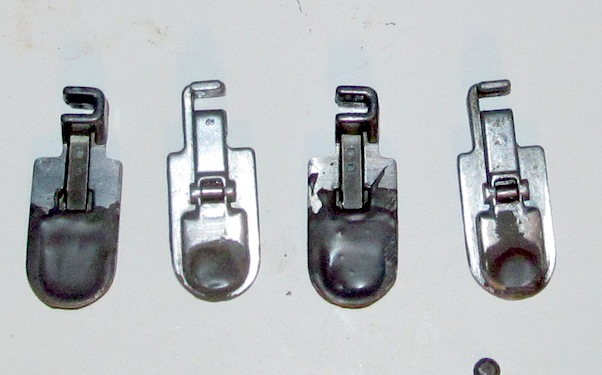

So, to start the re-wiring process i pulled the old harness, clipped off a few connectors that i can re-use, and started laying out new wiring runs, and then figured how out to mount a new fuse block. Sourced from Amazon the 6 circuit block has a common negative bus bar with individual positive circuits out. It took a little bit of finagling but figured out the easiest way to mount it was to take out the existing fuse mounting area on the left side, trim off the brackets to make it flat, and then drill mounting holes. New positive wiring comes into the sides, 12v power in from the bottom, out the top to separate negative lines.